The workover downhole operation simulators and the portable workover simulator primarily differ from one another in terms of their appearance and their capabilities in the workover process. Both the stationary workover downhole operation simulators and the portable workover downhole operation simulators come in a variety of configurations and serve a variety of purposes.

The term "portable workover simulator" refers to a small, mobile simulator device that is easy to carry around and can be set up in a variety of locations

This type of downhole operation simulator is ideal for use during workover operations

It is recommended that a simulator of this type be used whenever workover operations are being carried out

The package will typically include a portable computer, a display screen, a virtual reality headset, as well as a few different control options in order to provide a fundamental simulation experience

This is done so that the user will have the opportunity to experience the simulation

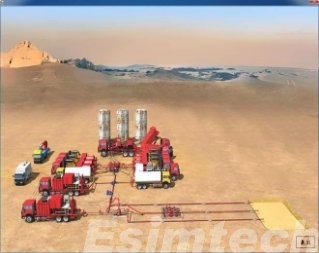

The Portable Workover Simulator is ideally suited for use in on-site training and operations that take place in the field due to its small size and the ease with which it can be moved from one location to another. This makes it an excellent choice for use in a variety of scenarios. Additionally, they make it possible for operators to simulate and train in the environment that they will actually be working in.

Traditional workover simulators are utilized most frequently in educational institutions as well as in specialized simulation labs. These are the most common settings for their deployment. The conditions in which they can carry out their operations could not be better suited to their needs. They typically have higher performance and complexity, which enables simulations to be run that are both closer to reality and cover a greater variety of drilling scenarios. This makes it possible to run simulations that are more accurate. These kinds of simulators are routinely used over extended periods of time for a wide variety of instructional and in-depth training purposes. The training can cover a variety of topics.

On the other hand, portable workover simulators are more convenient for on-site training and field operations because they are more compact and mobile than traditional workover simulators. These simulators are adaptable and can be used in a wide variety of settings. These simulators are versatile and can be applied in a wide variety of contexts because of their adaptability. These kinds of systems have been in existence for a considerable amount of time. When deciding which emulator to use for an application, the factors associated with the application's specific use cases and requirements are the ones that should be given the most weight in the decision-making process.

Which of the two simulators' use cases is most dissimilar to the other, and what actions can be taken to avoid the difficulties that may be brought on by the disparity between the two? The workover simulator can be moved from one location to another thanks to its portability. A place where classes and various other educational programs are presented to students. The majority of the time, workover simulators can be found in facilities that are specifically designed for the purpose of providing education and training. Drilling engineers and operators are able to receive comprehensive training at these centers thanks to the extensive training programs and simulation experiments that are provided by these centers.

2. The workover downhole operation simulators enables all of these applications to be carried out successfully. Additionally, the workover simulator can be utilized for the purpose of conducting research and development activities associated with workover procedures.

5. Drilling equipment research and development, in addition to quality control and assurance testingThe workover downhole operation simulators is utilized in the process of researching, developing, and testing drilling equipment to evaluate the effectiveness and dependability of the drilling equipment. At the location where the drilling is taking place, training will take place. The portable workover downhole operation simulators makes it possible to provide effective training and operation guidance at the location where drilling is taking place. This helps to ensure that drilling goes as smoothly as possible. Because they are lightweight and simple to set up, they are ideal for providing operators with simulation in addition to training that involves hands-on practice. Because of this, they are ideally suited for the role of providing either form of training to operators.

2. Operator evaluation with the assistance of portable workover simulators, an operator's skills, and capabilities can be evaluated by watching how well they perform in an environment that is analogous to the one in which they will actually be working. This allows for a more accurate depiction of the operator's potential output. The degree to which individuals are able to adjust to the various elements of their environment is one way in which this can be established.

5. Education and training in workover procedures made available by educational institutionsStudents can gain a better understanding of the operations and procedures that are involved in workovers by using portable workover simulators in the classroom setting as part of training courses that are taught in schools and colleges. Students might develop a higher level of expertise in their work as a result of this.