1. Introduction

In today's industries, computer-aided design (CAD) and computer-aided manufacturing (CAM) are essential tools that streamline the design and production processes of anything from consumer electronics to automobiles. CAM employs the complex electronic models created by CAD to direct production operations such as 3D printing and machining. CAD/CAM system integration has improved productivity, decreased errors, and spurred innovation in a number of sectors, including aerospace, automotive, and healthcare.

CAD/CAM is being revolutionized by Artificial Intelligence (AI), which optimizes industrial operations and design processes. Artificial intelligence algorithms are capable of analyzing large amounts of design data to find trends, optimizing designs based on performance or cost requirements, and even coming up with creative solutions on their own. Artificial Intelligence (AI) in manufacturing allows for real-time modifications to production schedules based on demand estimates, predictive maintenance, and quality control using image recognition systems. CAD/CAM technology can improve productivity, precision, and agility in the development and manufacturing processes by utilizing AI's capabilities.

2. Automation in Design Process

The design process's automation is essential for optimizing CAD/CAM workflows. Artificial intelligence (AI) makes it possible to automate repetitive design chores, such creating design iterations, which eliminates the need for constant manual intervention. Designers may precisely and efficiently optimize complex design processes by utilizing AI algorithms.

CAD design benefits from the inclusion of AI-driven automation in a number of ways. First off, it greatly increases productivity by cutting down on time spent on monotonous work, freeing up designers to concentrate more on originality and creativity. Automation reduces human error, which improves design correctness and consistency. In the end, this leads to quicker project completion dates and higher levels of production all around.

Using algorithms to explore a wide range of design choices based on given criteria, generative design software is one example of an AI application that helps with the CAD/CAM design process. These technologies facilitate the rapid generation of creative designs while taking a variety of goals and limits into account. Through the analysis of historical design data, machine learning algorithms can offer insights for improving future designs and help designers make well-informed decisions at every stage of the process.

The incorporation of AI-powered automation revolutionizes the CAD/CAM landscape by optimizing workflows, improving efficiency, and fostering innovation in design processes.

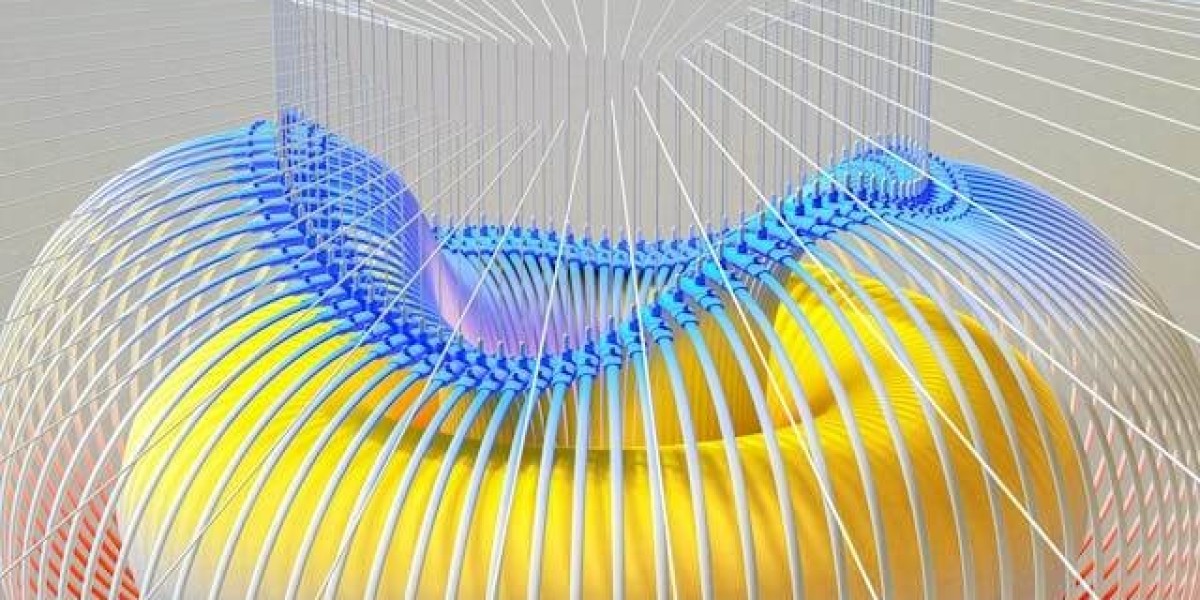

3. Optimization and Simulation Capabilities

AI is particularly good at improving designs for better performance and manufacturability in the CAD/CAM domain. Engineers can obtain better results by streamlining the design process and utilizing AI algorithms. Large volumes of data are analyzed by these algorithms, which then recommend design changes that guarantee ease of manufacture while also enhancing product performance. The product development cycle is accelerated and design iterations are greatly decreased by this optimization capacity.

AI is essential for replicating real-world situations in CAD/CAM to improve product development. Without the need for actual prototypes, engineers can test different design configurations fast and precisely using virtual simulations powered by AI. The capacity to model various situations aids in the early detection of possible problems during the design stage, resulting in cost savings and a quicker time to market. Through the use of AI-driven simulations, engineers may adjust designs in response to performance feedback, producing goods that either meet or surpass expectations.

The influence of AI on CAD/CAM design simulation and optimization is illustrated by a number of case examples. An instance of this may be seen in a manufacturing company that employed artificial intelligence algorithms to enhance the airflow in their goods, leading to increased energy efficiency and enhanced overall performance. Another case study demonstrates how one automaker tested various collision scenarios using AI simulations, which helped to build safer cars while cutting testing expenses. These illustrations show how AI's superior optimization and simulation capabilities may completely transform conventional design methods.

In summary, artificial intelligence's optimization and simulation powers are revolutionizing the CAD/CAM industry by empowering engineers to produce more effective, high-performing products. AI enables designers to develop quickly and repeatedly by simulating real-world settings and analyzing complex data sets. Artificial Intelligence (AI) incorporated into CAD/CAM processes leads to cost savings and faster time-to-market in addition to improved product quality. AI will likely become more and more important in determining how CAD/CAM firms develop and design products in the future as technology develops.

4. Enhancing Collaboration and Communication

Because AI facilitates smooth communication and collaboration between engineers, designers, and stakeholders, it is essential to CAD/CAM projects. Real-time feedback mechanisms enabled by AI-powered solutions enable team members to offer prompt insights and recommendations, resulting in expedited decision-making processes. By guaranteeing that everyone involved in the project is working on the most recent version of the designs, features like version control help to avoid mistakes caused by working on out-of-date files. AI integration improves communication by streamlining interactions and keeping all stakeholders informed and in sync throughout the project timeline. This is achieved through automatic updates, notifications, and reminders.

The way teams work together on CAD/CAM projects has changed dramatically as a result of these developments in AI technology, which has enhanced productivity and efficiency. AI systems, for example, are able to assess design data in real time, providing important insights into possible difficulties or improvements that can come up during the development process. Teams can use predictive analytics to foresee problems before they arise and implement proactive problem-solving techniques by utilizing AI for cooperation.

The incorporation of virtual reality (VR) platforms into CAD/CAM software serves as a concrete illustration of how AI technologies might enhance cooperation. With VR headsets, engineers and designers can jointly envision intricate 3D models in real time, facilitating seamless idea sharing and quick revisions regardless of geographical location. In addition to improving communication, this immersive experience encourages team members to work more creatively and dynamically together.

Using natural language processing (NLP) capabilities in CAD/CAM systems to make it easier for stakeholders with different technical backgrounds to communicate with one another is another example. NLP algorithms have the ability to comprehend user instructions or textual input and convert them into software interface design adjustments that can be implemented. By keeping communication simple, this project ensures that everyone involved may contribute to the development process without being hampered by complicated interfaces or technical jargon.

AI technology integration in CAD/CAM settings has greatly enhanced stakeholder, engineer, and designer cooperation and communication methods. Throughout the design process, project teams may maintain high standards of quality and creativity while working together more effectively by utilizing AI-powered solutions for version control, real-time feedback, and improved communication capabilities.

5. Future Trends and Challenges

A number of trends are influencing how CAD/CAM will develop in the future as AI develops. A major trend in design is generative design, which allows AI algorithms to generate a multitude of design options on their own by utilizing predefined parameters. In CAD/CAM systems, neural networks are essential because they improve pattern detection and optimization procedures. Autonomous systems that can automate labor-intensive design and production operations are another new trend.

Even with its bright future, CAD/CAM AI integration is not without its difficulties. As AI-driven systems handle and exchange sensitive design data, data security becomes critical. Due to the enormous volume of data collection required for AI model training, privacy concerns are raised. The workforce needs to be upskilled more and more in order to use and adjust to AI-driven CAD/CAM products. This calls for continuous training programs and professional development activities.

Industries hoping to remain inventive and competitive in this quickly changing technical landscape will need to navigate these obstacles while utilizing AI in CAD/CAM. Embracing the future of AI-driven CAD/CAM technology requires addressing data security concerns with strong encryption methods and access restrictions, putting privacy protections like anonymization techniques into place, and offering extensive employee training programs. Through proactive problem-solving and keeping abreast of emerging trends, organizations may set themselves up for success in this fast-paced digital age.